In the biogas and renewable natural gas (RNG) industry, there’s a common misconception that containerized systems are essential for effective operation and maintenance. Many potential clients believe that using containers is the best approach. However, at GraniteFuel Engineering, we challenge this misconception with a superior containerless design. Our biogas condition systems are designed specifically for real-world conditions, ensuring optimal performance, serviceability, and safety in diverse climates. By educating our customers on the benefits of container-free RNG systems, we help them save money and build better systems.

The Problem with Containers

Containerized systems have their origins in the need for ease of shipping, particularly for overseas transport. Using standard shipping containers allows for a straightforward and uniform packaging solution, making global distribution more manageable. This approach has made containerized designs a common choice in the RNG industry.

However, despite their initial appeal, containerized systems present several limitations and drawbacks when used for RNG applications:

- Heat Retention: Containers are not designed for effective heat dissipation. The enclosed space traps heat generated by compressors and other equipment, leading to increased temperatures that can affect the performance and longevity of the system. Proper cooling becomes a significant challenge, especially in warmer climates, potentially causing operational inefficiencies and increased maintenance requirements.

- Accessibility: Working within the confined space of a container can be highly restrictive. Technicians often struggle with limited maneuverability, making it difficult to access and service key components. This lack of space can lead to longer downtime during maintenance and repairs, increasing operational costs and reducing overall efficiency.

- Safety: Containers can pose safety risks for operators. The confined space can become hazardous, especially in the presence of potential gas leaks or other environmental hazards. Ensuring operator safety in such an enclosed environment requires additional safety measures and monitoring, which can be both costly and complex to implement effectively.

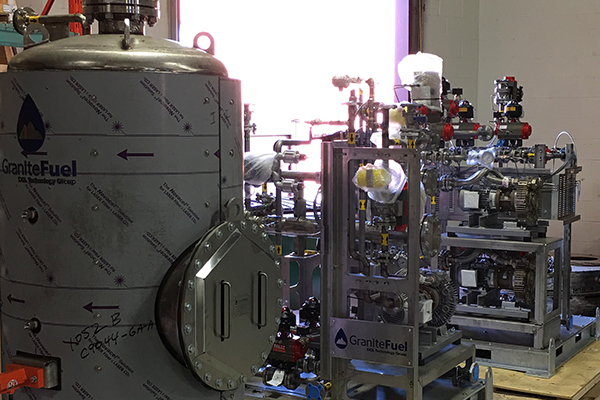

GraniteFuel Engineering recognized these challenges and have developed a container-free design that addresses these issues head-on. Our approach ensures that our RNG systems are not only more efficient and easier to maintain but also safer for operators, providing a superior solution for real-world operational needs.

Custom Solutions for Diverse Climates

RNG systems across North America face a wide range of environmental challenges. From the scorching heat of Arizona summers to the frigid winters of Quebec, these systems must be resilient and adaptable to perform reliably in diverse conditions.

GraniteFuel’s design is specifically tailored to withstand these extreme temperatures. We select and configure our components to ensure reliable performance regardless of climate. For instance, our compressors and control panels are designed to operate efficiently in open-air environments, allowing for natural heat dissipation in hot climates and reducing the risk of overheating.

In colder regions, such as the northern states and Canada, our design minimizes heat retention issues associated with containerized systems. By not enclosing our systems in containers, we avoid the challenges of insulating and heating these spaces, which can be both costly and inefficient. Instead, we use specialized enclosures for sensitive components like membranes, which are protected with integrated heaters and ventilation systems to prevent freezing and ensure optimal performance.

By designing our systems with these climate-specific considerations, we provide a robust and reliable solution that performs consistently across a wide range of environmental conditions.

Enhancing Serviceability and Efficiency

One of the primary benefits of GraniteFuel’s container-free design is the enhanced serviceability and efficiency it provides. The exposed, containerless configuration allows for quick and easy maintenance, significantly reducing downtime and operational costs.

- Easy Maintenance: With key components such as compressors and control panels easily accessible, technicians can perform maintenance and repairs more efficiently. This open design eliminates the need to work within the confined and often cramped spaces of containerized systems, making it easier to reach and service parts.

- Remote Monitoring: Our container-free RNG systems are equipped with advanced remote monitoring capabilities, allowing for real-time tracking and diagnostics. This technology reduces the need for on-site troubleshooting, as issues can often be identified and addressed remotely. When technicians require physical access, the exposed design ensures they can quickly and safely perform the necessary work.

- Specialized Design Features: GraniteFuel’s design includes features like sub-skidded compressors, which can be easily disconnected and removed for ex-situ servicing. This approach allows for more comprehensive maintenance and repairs in a controlled environment, rather than in the field.

Additionally, sensitive components like membranes are housed in specialized enclosures with removable panels. These enclosures provide necessary protection while still allowing for easy access when maintenance is required. This design shields the components from harsh environmental conditions without compromising accessibility.

By focusing on serviceability and efficiency, GraniteFuel’s container-free RNG systems offer a practical and cost-effective solution that meets the real-world needs of our customers.

Safety First In any industrial setting, safety is paramount. Containerized RNG systems can present significant safety risks, primarily due to the confined spaces they create. These enclosed environments can become hazardous, especially if there are gas leaks or other environmental hazards. The limited space within a container makes it difficult to maintain adequate ventilation and can complicate emergency responses.

Deliberate Exclusion of Frequent Access Points Another critical safety feature of GraniteFuel’s design is the deliberate exclusion of frequent access points in sensitive areas. By minimizing entry points, we reduce the likelihood of accidental exposure to hazardous conditions. Sensitive components, such as membranes, are housed in specialized enclosures that do not have doors for regular access. Instead, these enclosures are designed with removable panels, allowing for controlled and deliberate maintenance access only when necessary. This approach ensures that operators are not unintentionally exposed to potential hazards, enhancing overall safety.

Safety Monitors and Detectors To further ensure a secure operating environment, GraniteFuel’s systems are equipped with advanced safety monitors and detectors. These include H2S (hydrogen sulfide) monitors and LEL (lower explosive limit) detectors, which continuously monitor the air quality around the system. If any hazardous conditions are detected, the system can alert operators and take necessary actions to mitigate risks. These safety measures are crucial for maintaining a safe working environment and protecting both personnel and equipment.

GraniteFuel Engineering provides a secure and reliable RNG solution by prioritizing safety through our uncontainerized design, controlled access points, and advanced monitoring systems. Our solutions meet the highest safety standards.

For the renewable natural gas (RNG) industry, GraniteFuel Engineering’s innovative container-free design stands out for its practicality, efficiency, and safety. By challenging the conventional approach of containerized systems, we create and deliver solutions that suit real-world conditions better.

- Serviceability: Our exposed design facilitates quick and easy maintenance, reducing downtime and operational costs. The sub-skidded compressors and specialized enclosures ensure that critical components are accessible and easy to service.

- Technical Excellence: Tailored to withstand extreme temperatures, our systems perform reliably from the heat of Arizona to the cold of Quebec. The design optimizes heat dissipation and minimizes the challenges associated with insulating and heating containerized systems.

- Safety First: Our uncontainerized design mitigates safety risks by eliminating confined spaces and reducing accidental exposure to hazards. Additionally, it incorporates advanced safety monitors and detectors.

Don’t fall for the fake appeal of a container that will ultimately become a hindrance. GraniteFuel Engineering’s approach provides a superior solution that enhances serviceability, efficiency, and safety. Let us design your RNG system efficiently and effectively, without the cumbersome constraints of containerization.

Contact GraniteFuel Engineering today to learn more about how our innovative container-free RNG systems can meet your needs and deliver exceptional performance.