As the renewable energy sector continues to grow, biogas emerges as a key player in the drive towards sustainability. Originating from organic waste, biogas holds the potential to be refined into renewable natural gas (RNG), a clean and efficient alternative to traditional natural gas. Yet, the path from raw biogas to RNG involves several critical stages. Among them, biogas pretreatment stands out as a foundational step. This article explores the significance of biogas pretreatment and its role in ensuring the successful upgrading of biogas to RNG.

Setting the Stage: What is Biogas Pretreatment?

Before we delve into its importance, let’s define biogas pretreatment. It is the process of refining and cleaning raw biogas by removing impurities, contaminants, and certain gases. This step ensures that the biogas is of optimal quality and composition before it undergoes the upgrading process to become renewable natural gas (RNG).

The Multifaceted Importance of Pretreatment

1. Guarding the Upgrading Equipment

Raw biogas is not pure. It contains a cocktail of impurities, from hydrogen sulfide (H2S) to moisture and particulates. These can be detrimental to the upgrader, causing corrosion, fouling, and wear and tear. Pretreatment acts as a shield, protecting the upgrader from these potential threats.

2. Streamlining the Upgrading Process

Consistency is key for optimal performance. By ensuring that the biogas entering the upgrader is of consistent quality, pretreatment allows the upgrader to operate seamlessly and efficiently.

3. Safety First

Safety in the renewable energy sector is paramount. Some biogas impurities, notably H2S, are toxic. Pretreatment ensures a safer working environment by eliminating these hazards.

4. Elevating the End Product

Quality matters. By removing moisture, particulates, and other contaminants during pretreatment, the resulting RNG is of superior quality, with fewer impurities that could affect its combustion or other uses.

5. Economic Wisdom

Downtime and maintenance are costly. Pretreatment, by safeguarding the upgrader, reduces these costs. Moreover, with a consistent and high-quality biogas feed, the upgrader can maximize RNG yield, enhancing the return on investment.

6. Protecting the Environment

Renewable energy is about sustainability. Pretreatment removes harmful contaminants, which could have environmental repercussions if released. This step ensures that the RNG produced is as green as possible.

7. Meeting the Mark

Regulatory compliance is not just about avoiding penalties; it’s about upholding standards. Many regulatory bodies have set RNG quality benchmarks. Pretreatment ensures that the biogas, once upgraded, meets or exceeds these standards.

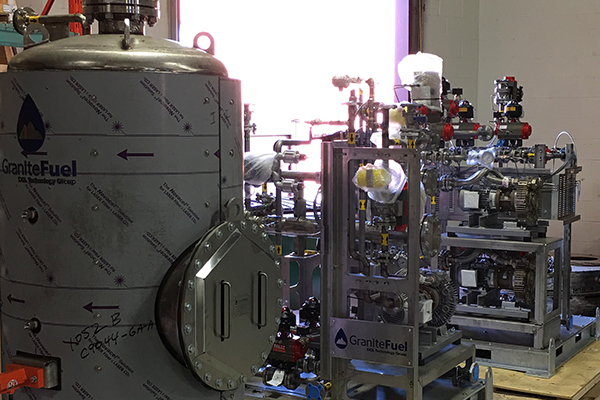

GraniteFuel Engineering: Pioneering Cost-Effective and Efficient Biogas Pretreatment

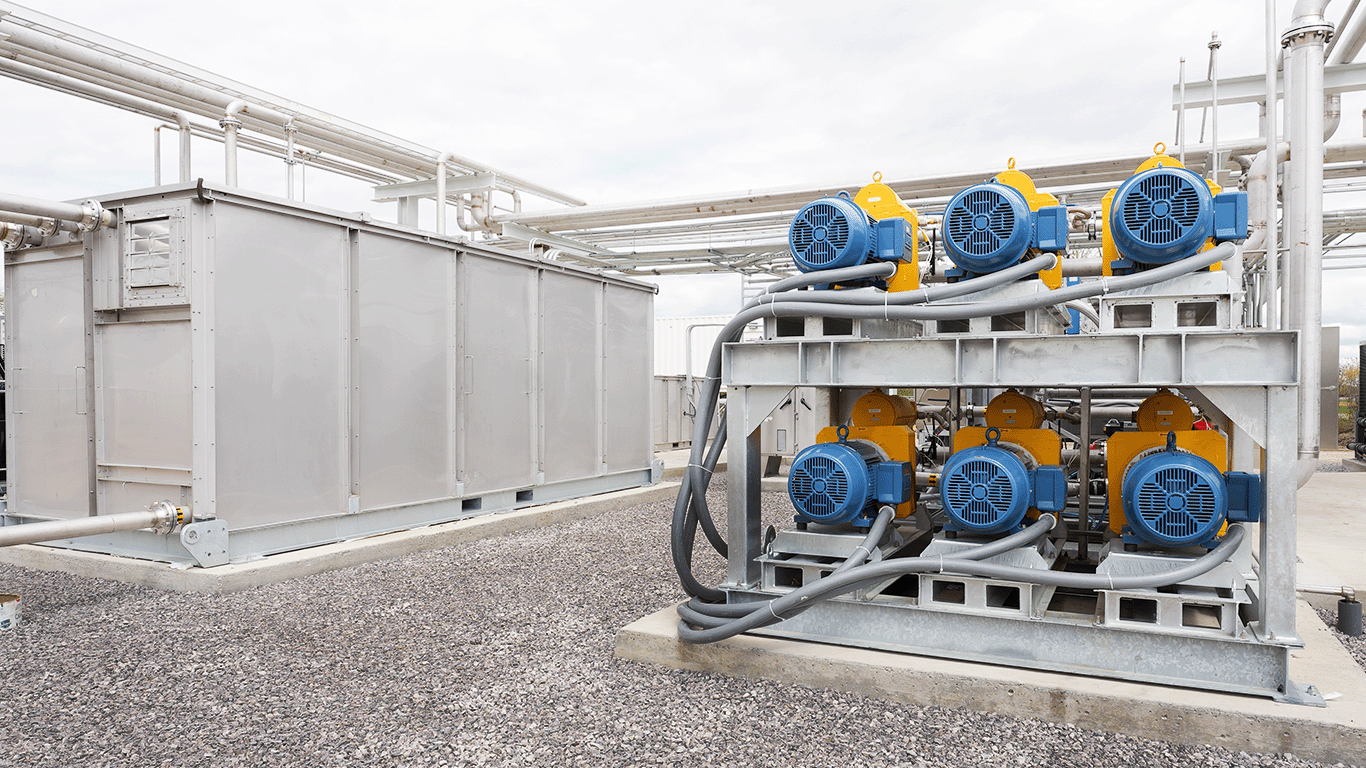

In the rapidly evolving world of renewable energy, biogas stands out as a sustainable and promising energy source. However, harnessing its full potential requires meticulous pretreatment. GraniteFuel Engineering, with its cutting-edge solutions, has positioned itself as a leader in this domain. Let’s explore in detail how GraniteFuel designs its biogas pretreatment systems to deliver the lowest operating costs, the highest uptime, and the maximum return on product gas.

Lowest Operating Costs

1. Advanced Technology Integration: GraniteFuel incorporates the latest technologies in its pretreatment systems. These technologies are not only efficient but also designed to minimize wear and tear, reducing maintenance costs.

2. Energy Efficiency: GraniteFuel’s systems are designed to consume minimal energy. By optimizing energy use, the systems ensure that operational costs remain low.

3. Modular Design: The modular design of GraniteFuel’s pretreatment systems allows for scalability. This means that as biogas production scales up, the system can be easily expanded without incurring significant costs.

4. In-House Expertise: By handling design, engineering, and manufacturing in-house, GraniteFuel eliminates the need for third-party interventions, which can often lead to additional costs.

Highest Uptime

1. Robust Design: GraniteFuel’s systems are built to last. By using high-quality materials and components, the systems are less prone to breakdowns and malfunctions.

2. Real-time Monitoring: Integrated sensors and monitoring tools ensure that any potential issues are detected early, allowing for proactive maintenance and minimizing downtime.

3. Quick Response Support: GraniteFuel’s dedicated support team ensures that any issues are addressed promptly, ensuring that the systems are up and running in the shortest possible time.

4. Continuous Upgrades: GraniteFuel believes in continuous improvement. By regularly upgrading their systems with the latest technologies and innovations, they ensure that the systems operate at peak efficiency at all times.

Maximum Return on Product Gas

1. Optimal Methane Recovery: GraniteFuel’s pretreatment systems are designed to maximize methane recovery, ensuring that the maximum amount of RNG is produced from the biogas.

2. Quality Assurance: By effectively removing impurities and contaminants, GraniteFuel ensures that the RNG produced is of the highest quality, fetching better prices in the market.

3. Regulatory Compliance: GraniteFuel’s systems ensure that the RNG produced meets all regulatory standards, ensuring that it can be sold or utilized without any compliance issues.

4. Environmental Benefits: By producing high-quality RNG, GraniteFuel’s systems contribute to reducing greenhouse gas emissions, positioning the RNG product as a premium, environmentally-friendly fuel source

A Transformative Process

The journey from raw biogas to renewable natural gas (RNG) is intricate, with each phase holding significant importance. Biogas pretreatment stands out as more than just a preparatory measure; it actively transforms the process, optimally priming biogas for upgrading. This step safeguards equipment, ensures safety, and guarantees the production of high-quality RNG.

GraniteFuel Engineering’s dedication to excellence shines through in its advanced biogas pretreatment systems. By emphasizing low operating costs, high uptime, and maximum return on product gas, GraniteFuel not only champions optimal performance but also amplifies the benefits for its clientele. As we navigate towards a more sustainable future, the role of biogas pretreatment and industry leaders like GraniteFuel becomes increasingly vital in steering the renewable energy domain.