In the renewable energy landscape, biogas derived from agricultural digesters stands out as a promising and sustainable energy source. As the world shifts towards greener energy solutions, the value of biogas, especially from agricultural waste, is increasingly recognized. However, to unlock its full potential, a crucial step is often required: biogas pretreatment. In this article, we delve into the significance of biogas pretreatment, the challenges it addresses, and the vast opportunities it unlocks, with a special focus on GraniteFuel Engineering’s expertise in this domain.

Why Biogas Pretreatment is Crucial for Agricultural Digesters

Agricultural digesters process organic waste materials, such as manure, crop residues, and other agricultural by-products, to produce biogas. This biogas, while a valuable energy source, contains impurities that can hinder its efficient utilization and even damage equipment.

- Protecting Equipment: Raw biogas contains contaminants like hydrogen sulfide (H2S), moisture, and particulates. These can corrode and damage equipment, leading to frequent maintenance, reduced equipment lifespan, and increased operational costs.

- Optimizing Energy Content: Pretreatment processes can enhance the calorific value of biogas by removing carbon dioxide and other non-combustible gases, making it a more efficient fuel source.

- Ensuring Safety: Some impurities in biogas, especially H2S, are toxic. Removing these contaminants ensures safer handling and utilization of the gas.

Challenges in Pretreating Biogas from Agricultural Digesters

- Variability in Biogas Composition: The composition of biogas can vary based on the feedstock used in the digester. For instance, manure from different animals or crops from different regions can produce biogas with varying levels of impurities. This variability requires flexible and adaptable pretreatment solutions.

- High Moisture Content: Agricultural digesters often produce biogas with high moisture content. Excessive moisture can lead to the formation of corrosive acids, especially when combined with H2S.

- Scalability: As agricultural operations expand or change, the volume and composition of biogas can change, requiring scalable pretreatment solutions that can handle increased gas volumes or different impurity levels.

Opportunities Post-Pretreatment

Once biogas undergoes thorough pretreatment, a world of opportunities opens up:

- Pipeline Injection: Pretreated biogas, also known as renewable natural gas (RNG), can be injected into natural gas pipelines, providing a renewable energy source for homes and businesses.

- Vehicle Fuel: RNG can be compressed and used as a clean-burning alternative to gasoline and diesel in vehicles.

- Electricity Generation: Pretreated biogas can be used in gas engines or turbines to generate electricity, either for on-site use or for feeding into the grid.

- Heat Production: Biogas can be combusted to produce heat for various agricultural processes, reducing the reliance on fossil fuels.

- Carbon Credits: By capturing and utilizing methane, a potent greenhouse gas, agricultural operations can earn carbon credits, which can be sold or used to offset other emissions.

GraniteFuel Engineering’s Expertise in Biogas Pretreatment

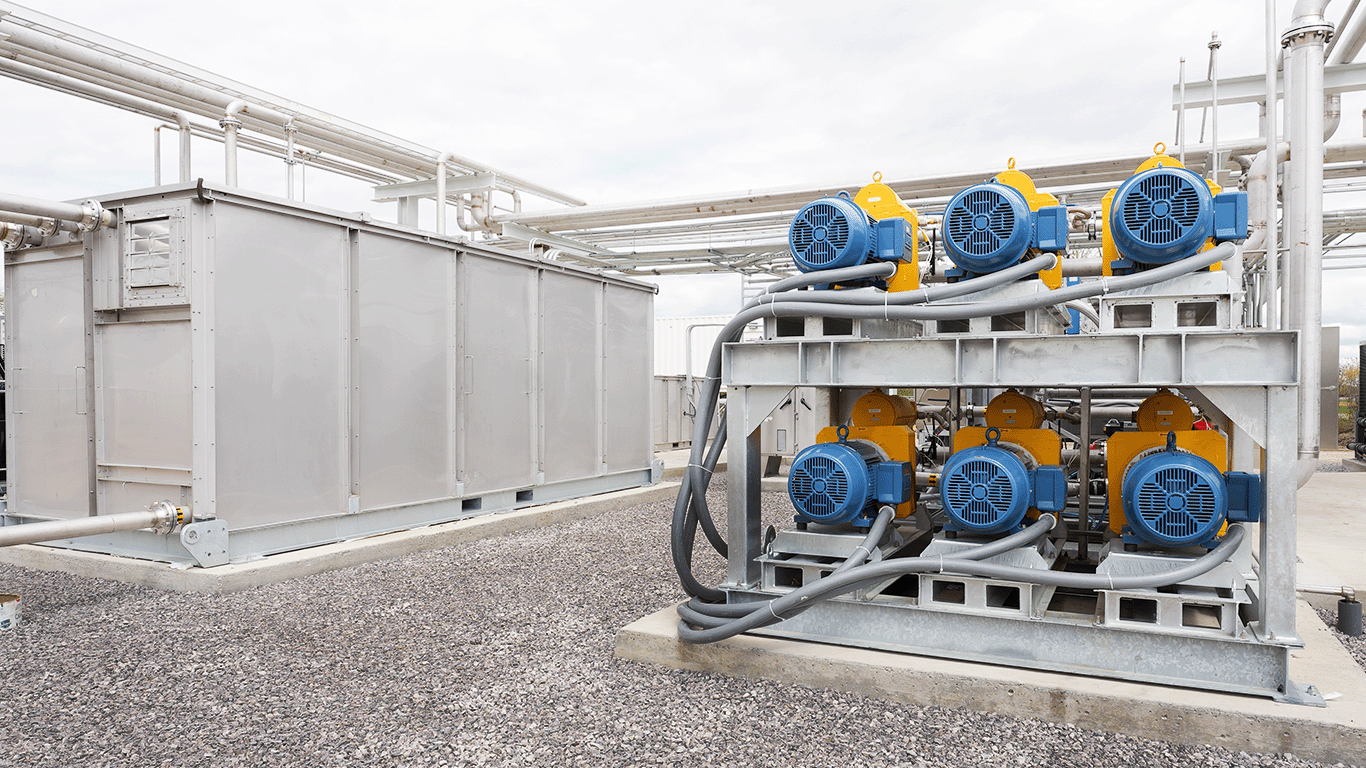

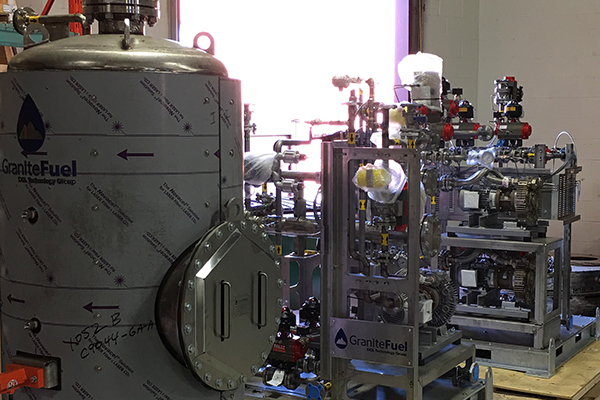

GraniteFuel Engineering stands at the forefront of biogas pretreatment technology. Recognizing the unique challenges posed by biogas from agricultural digesters, GraniteFuel designs systems that are both efficient and adaptable. Their state-of-the-art technologies ensure optimal removal of impurities, setting the stage for the efficient utilization of biogas in various applications. By prioritizing both the lowest possible operating costs and system reliability, GraniteFuel ensures that agricultural operations can maximize the benefits of their biogas production.

Conclusion

Biogas pretreatment is not just a necessary step; it’s a transformative one. It turns raw biogas from agricultural digesters into a versatile, efficient, and sustainable energy source. With the expertise of companies like GraniteFuel Engineering, agricultural operations can navigate the challenges of pretreatment and tap into the vast opportunities that high-quality biogas presents.