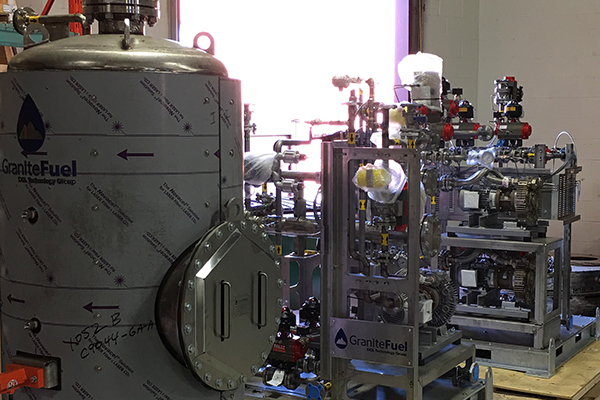

In the quest for sustainable energy solutions, Renewable Natural Gas (RNG) is gaining prominence. This renewable resource holds the promise of reducing our reliance on fossil fuels and mitigating the impacts of climate change. At the core of RNG production is the intricate yet vital process of biogas upgrading. But what does this entail? How do we transform raw biogas into a cleaner, more versatile fuel? In this comprehensive guide, we’ll delve deep into the science of biogas upgrading, with a special focus on the cutting-edge technologies and equipment that GraniteFuel Engineering offers.

What is Biogas and Why Does It Need Upgrading?

Biogas is a renewable energy source, typically produced from the anaerobic digestion of organic matter. This includes agricultural waste, sewage sludge, and landfill material. While the concept of using waste to generate energy is compelling, raw biogas is far from being a perfect fuel. It contains various impurities such as carbon dioxide (CO2), hydrogen sulfide (H2S), water vapor, and sometimes even ammonia (NH3). These impurities not only reduce the calorific value of the gas but can also be corrosive, posing challenges for storage and transportation.

This is where biogas upgrading comes into play. The process aims to remove these impurities, enriching the methane content of the gas. The result is Renewable Natural Gas (RNG), a cleaner and more efficient fuel that can be used in a variety of applications, from RNG plant equipment to RNG injection into the gas grid.

The Role of Biogas Conditioning Systems

Biogas conditioning systems are the backbone of any successful biogas upgrading solution. These systems are designed to treat and purify raw biogas, making it suitable for its intended end-use. At GraniteFuel Engineering, we specialize in several key components and processes that make this transformation possible.

H2S Removal

Hydrogen sulfide is a corrosive and toxic gas that can severely damage RNG plant equipment and pose health risks. Our advanced H2S removal systems use specialized filtering techniques to eliminate this harmful compound, ensuring that the resulting RNG meets the highest quality and safety standards.

Biogas Dehydration

Water vapor is another common impurity in raw biogas. While it may seem harmless, moisture can lead to pipeline corrosion and significantly reduce combustion efficiency. GraniteFuel’s state-of-the-art biogas dehydration units are designed to remove this moisture, thereby enhancing the quality and usability of the RNG produced.

Biogas Compression

For RNG to be effectively stored or transported, it needs to be compressed. Our biogas compression systems are engineered for maximum efficiency and reliability, making them an indispensable component in any RNG plant development project. These systems use advanced compression techniques to reduce the volume of the gas, preparing it for storage or pipeline injection.

Membrane Separation

One of the technologies that GraniteFuel employs for biogas upgrading is membrane separation. This involves using a semi-permeable membrane to separate methane from other gases like CO2. The technology is less energy-intensive compared to other methods and offers high levels of purity, making it a preferred choice for many RNG projects.

NH3 Removal

Ammonia is another impurity that can be found in biogas, especially when the feedstock includes agricultural waste or sewage sludge. High levels of ammonia can be problematic for both storage and combustion. Our NH3 removal systems use specialized filtering techniques to efficiently eliminate this impurity, ensuring that the RNG produced meets stringent quality standards.

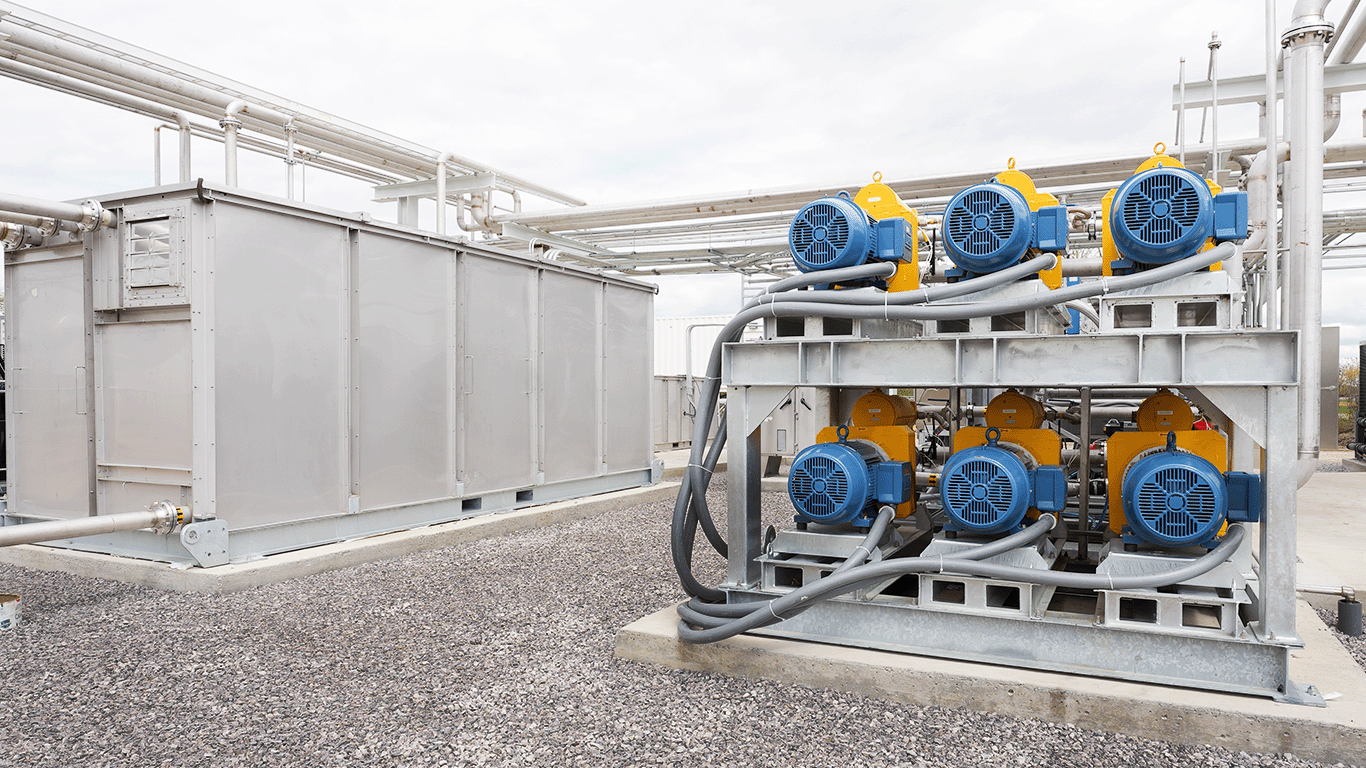

Blower Systems

Effective gas flow is crucial for the entire upgrading process. Our blower systems are engineered to ensure that biogas moves efficiently through each stage of the conditioning system. These systems use advanced aerodynamic technologies to optimize flow rates, thereby enhancing the overall efficiency of the biogas upgrading process.

Activated Carbon Polishing

Even after the primary upgrading process, RNG may still contain trace impurities that need to be removed to meet specific quality standards, especially for RNG injection into the gas grid. Our activated carbon polishing units are designed to capture these trace elements, delivering RNG of the highest quality.

Unique Technologies: Regenerative Temperature Swing Adsorption

While many biogas upgrading solutions rely on conventional methods like Pressure Swing Adsorption, GraniteFuel Engineering specializes in a unique technology known as Regenerative Temperature Swing Adsorption. This process leverages temperature variations to adsorb and desorb gases, offering higher efficiency and lower operational costs. It represents a significant advancement in RNG production technology, setting new standards for efficiency and reliability.

The Multifaceted Applications of RNG

The upgraded RNG has a multitude of applications. It can use to power reciprocating engines for electricity generation, utilized in turbines for larger-scale energy production, and injected directly into the gas grid. The versatility of RNG makes it a cornerstone in our transition to a more sustainable energy landscape.

The Future is Bright with RNG

Biogas upgrading is a complex yet crucial process that holds the key to unlocking the full potential of RNG. Through specialized technologies like Regenerative Temperature Swing Adsorption and advanced biogas conditioning systems, GraniteFuel Engineering is pioneering the way in RNG plant development.

Understanding the science behind biogas upgrading is not just an academic exercise. It’s a critical step toward a cleaner, more sustainable future. As we continue to innovate and improve RNG production technology, the role of biogas upgrading in shaping a sustainable energy landscape becomes increasingly significant.

By diving deep into the intricacies of biogas upgrading, we hope to shed light on this vital process, contributing to the broader understanding and adoption of RNG as a viable, renewable energy source.