In the quest for sustainable energy solutions, biogas stands out as a promising candidate. However, the journey from raw biogas to high-quality renewable natural gas (RNG) is not as straightforward as it might seem. One of the pivotal steps in this transformation is biogas pretreatment. In this article, we’ll explore the potential consequences of bypassing this crucial step and delve into how GraniteFuel’s integrated approach ensures optimal RNG production.

The Risks of Skipping Pretreatment

1. Equipment Damage: Raw biogas is laden with contaminants, notably hydrogen sulfide (H2S), which is highly corrosive. Without pretreatment, this can lead to accelerated wear and tear, reducing equipment lifespan and hiking up maintenance costs.

2. Operational Efficiency: Impurities present in raw biogas can hinder the upgrading process, leading to suboptimal RNG yields.

3. Safety First: Certain contaminants, such as H2S, pose significant health risks. Bypassing pretreatment can jeopardize the safety of both workers and the surrounding environment.

4. Maintenance Overheads: The presence of impurities can result in fouling, blockages, and frequent system shutdowns for maintenance, leading to operational inefficiencies.

5. Compromised RNG Quality: RNG produced without adequate pretreatment might contain impurities that adversely affect its combustion properties, leading to potential issues during its end-use.

6. Regulatory Hurdles: For RNG to be injected into the natural gas grid or used as vehicle fuel, it must adhere to specific quality standards. Without pretreatment, meeting these standards becomes a challenge, potentially leading to regulatory penalties.

7. Economic Implications: The amalgamation of increased maintenance, reduced RNG yield, and potential regulatory fines can render the upgrader’s operation economically challenging.

8. Environmental Setbacks: RNG is celebrated for its environmental benefits. However, without pretreatment, the RNG produced might result in increased emissions upon combustion, undermining its green credentials.

Unique Considerations in the Biogas Pretreatment Process

Biogas, while a promising renewable energy source, is derived from the anaerobic digestion of organic materials, which means it inherently contains a mix of gases and contaminants. Addressing these impurities is crucial to ensure the efficient production of RNG. Here are some unique considerations and contaminants that need to be addressed during the pretreatment process:

Hydrogen Sulfide (H2S)

One of the primary contaminants in biogas is hydrogen sulfide. Not only is H2S corrosive, potentially leading to equipment damage, but it’s also toxic. High concentrations of H2S can pose health risks, making its removal essential. Additionally, when burned, H2S can transform into sulfur dioxide (SO2), a pollutant that can contribute to acid rain.

Siloxanes

Siloxanes are compounds often found in biogas derived from wastewater treatment plants due to their prevalence in personal care products. When combusted, siloxanes convert into silicon dioxide, which can deposit on equipment surfaces, leading to wear and tear and reducing the equipment’s operational lifespan.

Moisture

Water vapor is a common component of biogas. Excessive moisture can lead to the formation of corrosive compounds, especially when combined with other contaminants like H2S. Removing moisture is crucial to prevent corrosion and ensure the efficient operation of upgrading equipment.

Carbon Dioxide (CO2)

While not a contaminant in the traditional sense, the concentration of CO2 in biogas can impact the efficiency of the upgrading process. Reducing the CO2 content is essential to increase the methane concentration in the resulting RNG.

Ammonia (NH3)

Ammonia is another compound that can be found in biogas, especially when the feedstock includes livestock manure. High concentrations of ammonia can be corrosive and can also impact the efficiency of certain upgrading processes.

Halogenated Compounds

These compounds, which include chlorinated and fluorinated hydrocarbons, can be present in biogas, especially when the feedstock includes industrial waste. When combusted, halogenated compounds can produce corrosive and toxic byproducts.

GraniteFuel’s Comprehensive Pretreatment Solutions

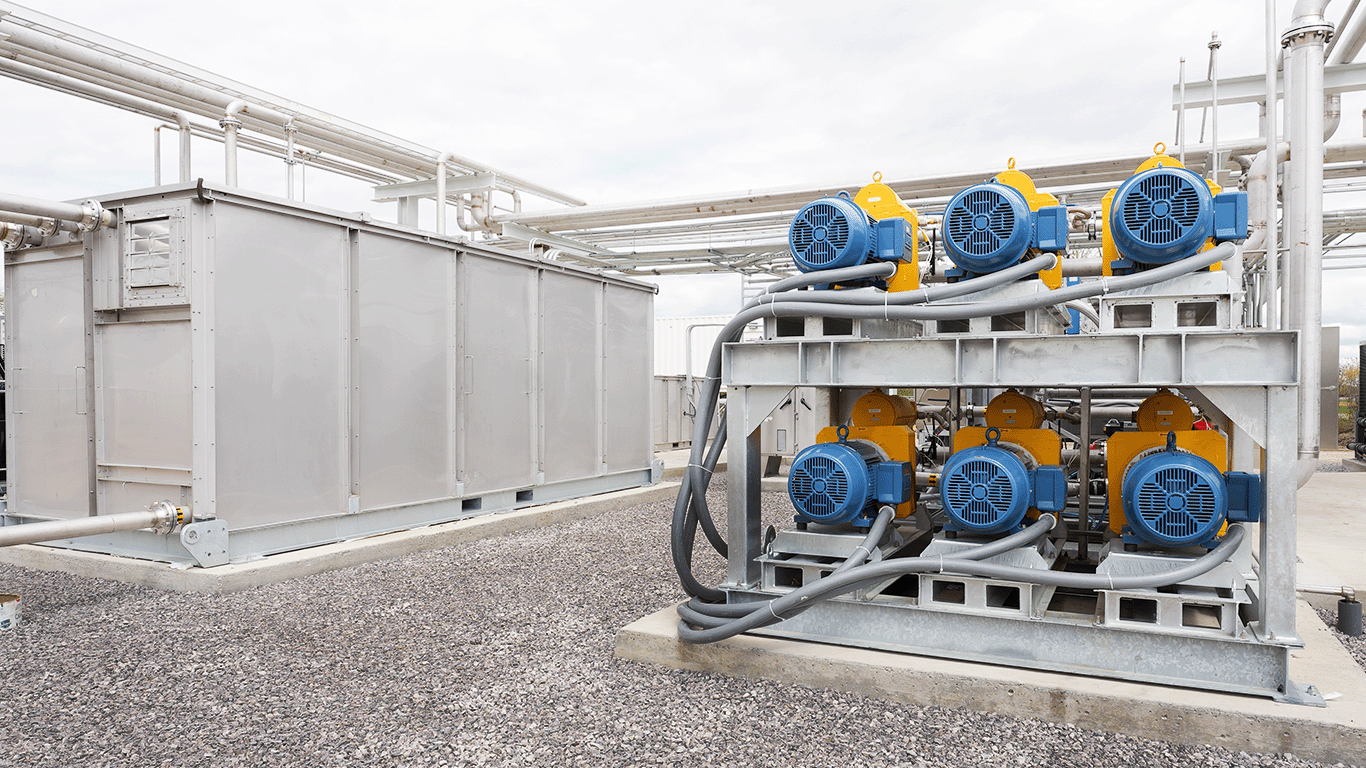

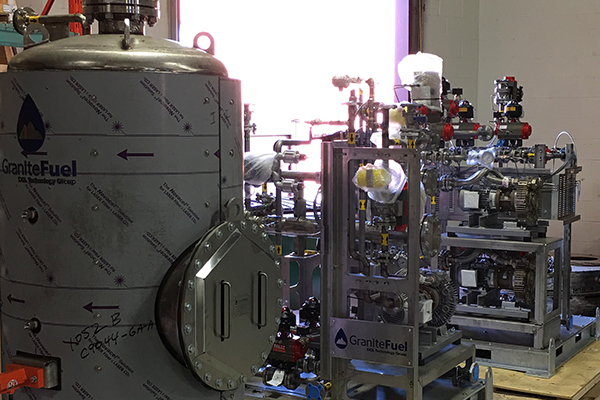

Understanding the diverse range of contaminants that can be present in biogas, GraniteFuel has developed a comprehensive suite of pretreatment solutions. Our systems are designed to address each of these contaminants effectively, ensuring that the biogas is primed for the upgrading process. By leveraging advanced technologies and our in-depth expertise, we ensure that our pretreatment solutions offer both efficiency and reliability, setting the stage for the production of high-quality RNG.

With these added considerations, the importance of biogas pretreatment becomes even more evident. It’s not just about ensuring the efficient production of RNG but also about safeguarding equipment, ensuring regulatory compliance, and producing RNG that offers optimal combustion properties.

GraniteFuel’s Integrated Approach to Biogas Upgrading

At GraniteFuel, we recognize the intrinsic value of pretreatment in the RNG production process. Our commitment to excellence and sustainability drives us to design and manufacture both biogas pretreatment and upgrading systems in-house. This integrated approach offers several advantages:

Optimized Compatibility: Since both the pretreatment and upgrading systems are designed and manufactured under the same roof, they are inherently optimized to work seamlessly together.

High-Quality RNG: Our systems ensure that the RNG produced is of the highest quality, meeting all regulatory standards and offering optimal combustion properties.

Economic Benefits: By ensuring high efficiency and low maintenance, our systems offer long-term economic benefits, ensuring the highest return on RNG.

Reliability: With everything designed and manufactured in-house, we have complete control over the quality and performance of our systems, ensuring reliability and longevity.

In Conclusion

Biogas pretreatment is not just a step in the RNG production process; it’s a cornerstone. By ensuring that raw biogas is adequately cleaned and refined before upgrading, we can guarantee the production of high-quality RNG that offers both economic and environmental benefits. At GraniteFuel, our integrated approach to biogas upgrading ensures that our clients receive the best possible return on their investment, both in the short and long term.