Renewable Natural Gas (RNG) is increasingly gaining attention as a critical element in the transition to a more sustainable energy landscape. While the concept of RNG is straightforward—converting organic waste into usable gas—the actual process involves a complex interplay of various components and technologies. In this comprehensive guide, we’ll delve into the anatomy of an RNG plant, breaking down its key components. We’ll also highlight how GraniteFuel Engineering brings specialized expertise to the table, particularly in the realm of biogas conditioning and upgrading.

Feedstock Collection and Storage

Feedstock Storage

The journey to RNG begins with the collection and storage of organic waste materials. Whether it’s agricultural waste, landfill gas, or wastewater, these feedstocks serve as the raw material for biogas production. Storage solutions can range from simple containers to complex silos, depending on the type and volume of the feedstock. Proper storage is crucial to prevent premature decomposition and to ensure a consistent supply to the anaerobic digester.

Feedstock Pre-treatment

Before the feedstock can be used for biogas production, it often undergoes a pre-treatment process. This could involve sorting, shredding, or even chemical treatment to remove contaminants like plastics or metals. The aim is to prepare the feedstock for efficient anaerobic digestion, thereby ensuring a cleaner and more potent biogas output.

Anaerobic Digestion

Anaerobic Digester

The anaerobic digester is the core component where the magic happens. In this oxygen-free chamber, specialized microbes break down the organic matter to produce raw biogas. The design of the digester can vary based on the feedstock and the desired rate of gas production. Some advanced designs even allow for multi-stage digestion, where different groups of microbes act in sequence to optimize biogas production.

Heating System

Temperature control is critical for efficient anaerobic digestion. Microbes are sensitive to temperature changes, and each type of microbe has an optimal temperature range where it performs best. The heating system, therefore, plays a pivotal role in maintaining this optimal temperature, often using heat exchangers or direct heating methods to keep the digester at the right temperature.

Mixing System

Uniformity is key in anaerobic digestion. The mixing system ensures that the feedstock, microbes, and heat are evenly distributed throughout the digester. This uniformity allows for more efficient biogas production and prevents the formation of “dead zones” where digestion is less effective. Various types of mixing systems are used, including mechanical mixers and gas recirculation methods.

Biogas Collection

Gas Collection Dome/Cover

Once the biogas is produced, capturing it effectively is crucial. Gas collection domes or covers are designed to seal the digester, preventing the escape of valuable methane into the atmosphere. These systems are often made of specialized materials that can withstand the corrosive elements found in biogas.

Gas Storage

After collection, the biogas is stored temporarily until it’s ready for conditioning and upgrading. Storage solutions can range from simple gas holders to more complex pressurized vessels. The choice of storage solution often depends on the volume of biogas produced and the specific requirements of the downstream processing steps.

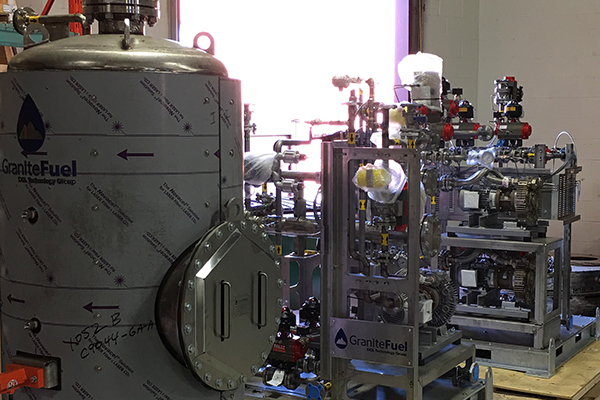

Biogas Conditioning and Upgrading by GraniteFuel

GraniteFuel Engineering specializes in designing and engineering all the components required for biogas conditioning and upgrading. Our systems are custom-designed to meet the unique requirements of each RNG plant, factoring in elements related to quality, monitoring, offtake, and safety.

H2S Removal System

Hydrogen sulfide (H2S) is a corrosive and toxic component commonly found in raw biogas. If not removed, H2S can corrode equipment and pipelines, leading to costly maintenance and potential safety hazards. GraniteFuel’s advanced H2S removal systems use chemical or physical methods to effectively eliminate this impurity, extending the lifespan of plant equipment and improving the quality of the RNG produced.

CO2 Removal System

Carbon dioxide (CO2) is another major impurity in raw biogas. While not as corrosive or toxic as H2S, CO2 dilutes the energy content of the gas. Our CO2 removal systems use advanced technologies like membrane separation or regenerative temperature swing adsorption to increase the methane content, making the RNG more energy-dense and suitable for various applications.

Water Vapor Removal (Dehydration)

Moisture is often overlooked but can be a significant issue in biogas processing. Water vapor can lead to corrosion, reduce the efficiency of compression systems, and even form ice plugs in pipelines during cold weather. GraniteFuel’s dehydration systems use techniques like condensation or adsorption to remove water vapor, ensuring the longevity and performance of downstream equipment.

Ammonia Removal

Depending on the feedstock and the intended end-use of the RNG, ammonia removal may be necessary. Ammonia can be harmful when the RNG is used in certain combustion processes and can also contribute to air pollution. GraniteFuel offers specialized ammonia removal systems that can be integrated into the overall biogas upgrading process.

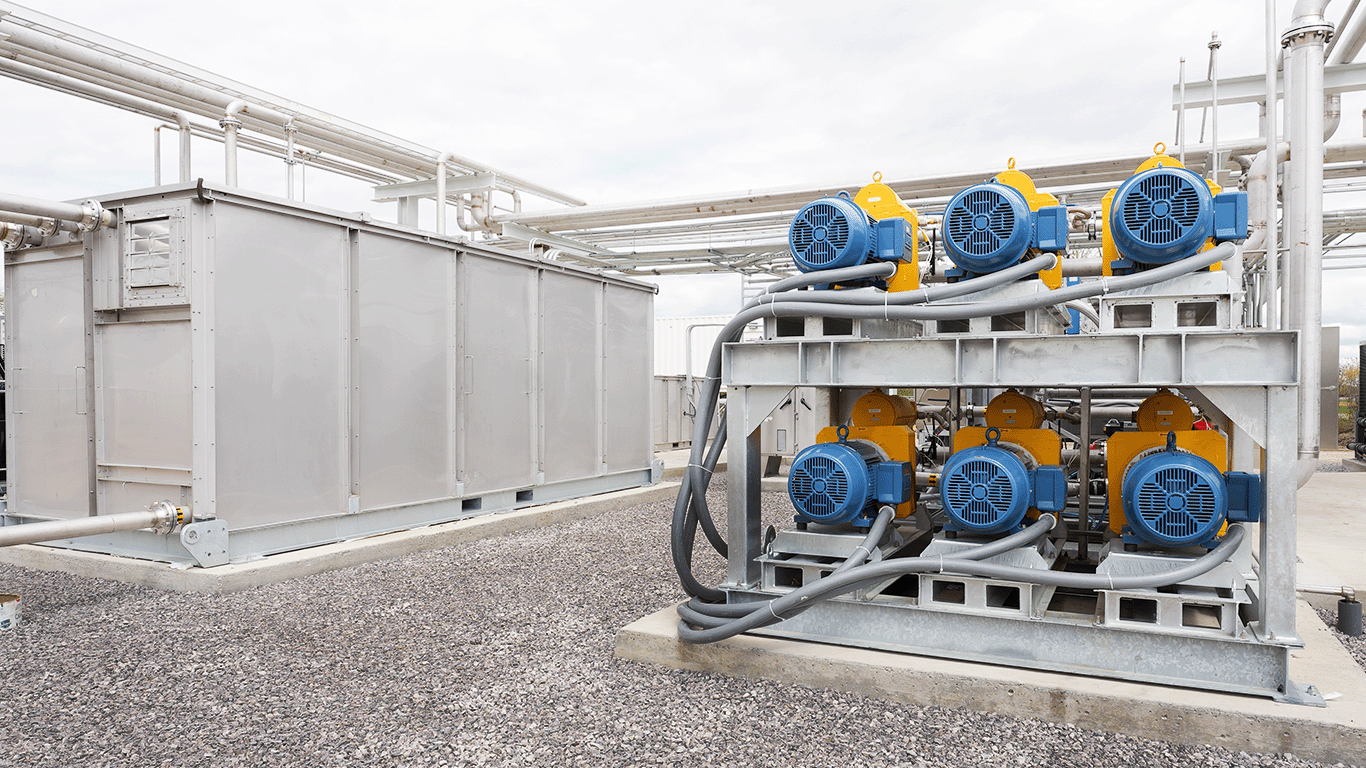

Biogas Compression

Once the biogas has been conditioned and upgraded, it needs to be compressed for transportation or storage. GraniteFuel’s state-of-the-art biogas compression systems are designed to handle the specific pressures required for various end-use applications, whether it’s pipeline injection or use as vehicle fuel.

Temperature Control

Temperature control is crucial during the upgrading process to ensure optimal performance of various components. GraniteFuel provides temperature control solutions that can be integrated into the overall system, maintaining the biogas at optimal conditions during the upgrading process.

Advanced Upgrading Technologies

GraniteFuel Engineering is at the forefront of implementing advanced technologies for further purification and upgrading of biogas to RNG. Whether it’s membrane separation technologies or our unique regenerative temperature swing adsorption systems, we offer solutions that set new benchmarks for efficiency and reliability in RNG production.

Quality Control and Monitoring

Gas Analyzers

Continuous monitoring is crucial for ensuring the quality and safety of RNG production. GraniteFuel’s systems are designed to integrate seamlessly with advanced gas analyzers, providing real-time data on the composition and quality of the RNG. This allows for immediate adjustments to the process parameters, ensuring consistent RNG quality.

RNG Offtake

RNG Dispensers and Pipeline Injection Systems

The final RNG product can be used in various applications, from vehicle fuel to pipeline injection for residential heating. GraniteFuel designs and engineers the offtake systems to meet the specific requirements of each application, whether it’s high-pressure dispensers for vehicle fueling or specialized systems for pipeline injection.

Safety Systems

Venting Systems, Fire Suppression, and Alarms

Safety is a paramount concern in any industrial process, and RNG production is no exception. GraniteFuel’s designs incorporate advanced safety features, including venting systems for controlled release of gases, fire suppression mechanisms to control and extinguish any accidental fires, and alarms and sensors to monitor various safety parameters like pressure, temperature, and potential gas leaks.

Complexities of Biogas to RNG

Creating RNG from raw biogas is a complex but rewarding process that involves a multitude of components and stages. At GraniteFuel Engineering, we bring specialized expertise to design and engineer key elements, particularly in the areas of biogas conditioning and upgrading. Our focus on quality, monitoring, offtake, and safety ensures that our RNG plant not only meet but exceed industry standards. By understanding the intricate components that go into an RNG plant, you can better appreciate the innovations and technologies that make RNG a sustainable and viable energy source for the future.