In the vast landscape of global industries, agriculture stands out as both a vital provider of sustenance and a significant contributor to environmental challenges. As the world grapples with the pressing issues of climate change, food security, and sustainable resource management, the agricultural sector finds itself at the crossroads of these converging challenges. While traditional farming practices have inadvertently contributed to greenhouse gas (GHG) emissions, there’s a silver lining.

With innovative technologies and sustainable practices, farms have the potential to not only mitigate their environmental impact but also to actively contribute to a greener future. GraniteFuel’s biogas pretreatment equipment and membrane upgraders are at the forefront of this transformative journey, offering farms a sustainable pathway to manage waste, reduce emissions, and harness renewable energy.

By capturing methane, a potent greenhouse gas, and transforming it into renewable natural gas (RNG), GraniteFuel’s systems are revolutionizing how farms manage waste and emissions, paving the way for a more sustainable agricultural future.

Methane: A Potent GHG and an Energy Goldmine

Methane is a greenhouse gas that doesn’t get as much attention as carbon dioxide, but its impact on the environment is profound. Over a 20-year period, methane is over 80 times more effective at trapping heat in the atmosphere than carbon dioxide, and over a 100-year period, it’s still over 25 times more potent. This makes its management crucial in the fight against global warming.

Agricultural activities, especially those related to livestock like cattle, are significant producers of methane. When organic matter breaks down in the absence of oxygen, as in the digestive systems of ruminants or in manure storage systems, methane is produced. This process, while natural, has been exacerbated by modern farming practices and the sheer scale of global livestock operations.

However, this methane, while a challenge, also presents an opportunity. Instead of allowing it to escape into the atmosphere, it can be captured and used as a valuable energy resource. This is where GraniteFuel’s systems come into play. By capturing this methane and converting it into renewable natural gas (RNG) through their advanced membrane upgraders, farms can transform a potent GHG into a clean energy source. This RNG can then be used on-site, fed into the national grid, or even used as a fuel for vehicles, displacing the need for fossil fuels and further reducing GHG emissions.

Beyond Methane: Addressing Other Emissions

While methane is a primary concern, biogas from agricultural sources contains several other contaminants that need to be addressed to ensure the gas is suitable for use and to minimize environmental impact.

One such contaminant is hydrogen sulfide (H2S). Present in varying concentrations in biogas, H2S is corrosive and can damage equipment. Moreover, when burned, it transforms into sulfur dioxide (SO2), a significant air pollutant known to cause respiratory problems in humans and contribute to the formation of acid rain.

GraniteFuel’s pretreatment equipment is meticulously designed to remove H2S, ensuring the resulting RNG is not only of high quality but also environmentally friendly. By effectively removing H2S and other contaminants, GraniteFuel ensures that the RNG produced is of the highest quality, burns cleanly, and minimizes emissions.

But H2S is not the only concern. Biogas can also contain other potential pollutants such as ammonia, siloxanes, and halogenated compounds. Each of these can have detrimental effects on equipment and the environment if not properly managed. Ammonia, for instance, can be corrosive, while siloxanes can lead to the formation of hard silica deposits on equipment surfaces when combusted.

GraniteFuel’s comprehensive pretreatment solutions address each of these contaminants, ensuring that the biogas is primed for the upgrading process and that the resulting RNG offers optimal combustion properties with minimal environmental impact.

Carbon Sequestration: A Step Towards Negative Emissions

During the biogas upgrading process, methane is separated from carbon dioxide. While methane is converted into RNG, the separated CO2 offers opportunities for sequestration or utilization in other applications. This not only prevents CO2 release but also moves us closer to achieving negative emissions – a crucial goal in the fight against climate change.

Waste Not, Want Not: The Circular Economy in Action

By converting organic waste into biogas, farms can significantly reduce waste disposal needs. This circular approach not only minimizes methane emissions from decomposing waste but also promotes resource efficiency and sustainability.

Economic and Sustainability Benefits

Adopting GraniteFuel’s systems can lead to significant energy cost savings for farms. Moreover, by reducing GHG emissions, farms can potentially earn carbon credits, providing an additional revenue stream. This economic incentive, combined with the environmental benefits, makes GraniteFuel’s solutions a win-win for both farmers and the planet.

Spotlight on Success: Alliance Dairy RNG Plant in Florida

In the realm of renewable energy, real-world applications often provide the most compelling narratives. The Alliance Dairy RNG plant in Florida stands as a testament to the transformative power of biogas pretreatment and upgrading.

Alliance Dairy, a major dairy farm in Florida, produces significant amounts of manure and dairy farm waste daily. Recognizing the potential of this waste, the farm collaborated with their local gas utility company to convert this waste into a valuable, renewable energy resource. As they embarked on this ambitious project, the utility company, recognizing the need for top-tier equipment, selected GraniteFuel’s advanced biogas solutions.

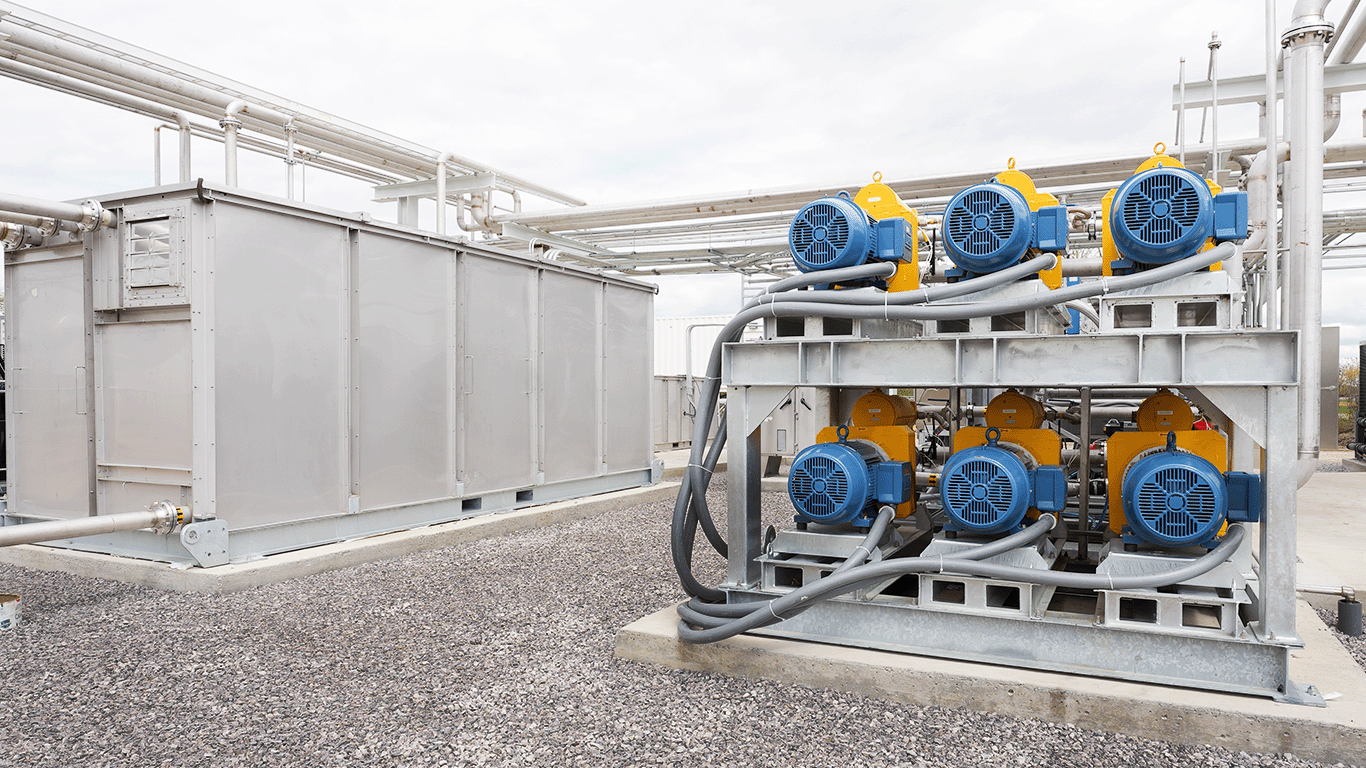

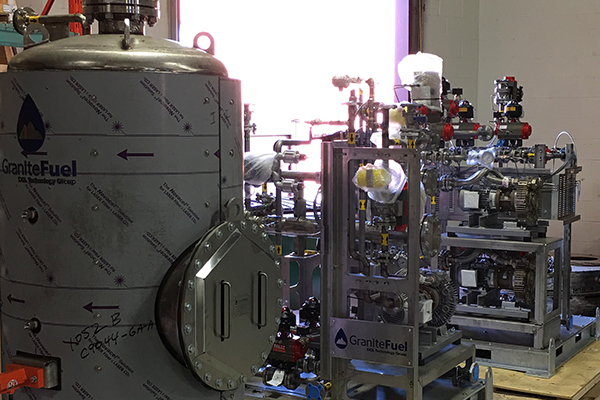

GraniteFuel’s proven pretreatment equipment was integrated into the facility to effectively clean the biogas derived from the dairy’s waste. This ensured the removal of contaminants, making the gas ready for the upgrading process. Following pretreatment, the biogas was introduced to GraniteFuel’s membrane separation upgrader, which transformed the biogas into high-quality renewable natural gas (RNG) that met stringent pipeline specifications.

Today, the Alliance Dairy RNG plant stands as a pioneer of renewable energy, producing pipeline-grade natural gas directly from dairy farm waste. This RNG is seamlessly integrated into the national gas grid, providing a sustainable energy source for countless households and businesses.

The success of the Alliance Dairy RNG plant underscores the potential of biogas pretreatment and upgrading. It highlights GraniteFuel’s pivotal role in providing top-tier equipment that drives such transformative projects, paving the way for a more sustainable energy landscape.

Summary

The journey from agricultural waste to renewable energy is a complex yet rewarding one. As the Alliance Dairy RNG plant in Florida demonstrates, with the right vision, collaboration, and equipment, farms can become pioneers in the renewable energy sector. GraniteFuel’s advanced biogas solutions play a crucial role in this transformation, ensuring that biogas is effectively pretreated and upgraded to meet the highest standards.

As we continue to seek sustainable solutions to our energy needs, the success stories of facilities like the Alliance Dairy RNG plant serve as a beacon of hope and a testament to the possibilities that lie ahead. With companies like GraniteFuel leading the way with their innovative equipment and expertise, the future of renewable energy looks brighter than ever.